Application of TPU Materials in Automotive Seats

TPU (Thermoplastic Polyurethane) is increasingly becoming a key material in automotive seating due to its exceptional wear resistance, elasticity, environmental friendliness, and processability. It is widely used in seat surfaces, side bolsters, and functional components. Below is a detailed analysis of TPU's applications and future trends in automotive seats.

1. Key Applications of TPU in Automotive Seats

(1) Seat Surface Covering

Alternative to Leather/PU: TPU leather offers a premium feel similar to genuine leather but with superior scratch and abrasion resistance (e.g., Tesla Cybertruck’s TPU-coated fabric seats).

Stain & Liquid Resistance: Its dense surface repels spills (coffee, oils), making it ideal for family and shared vehicles.

(2) Side Bolsters & Support Structures

Dynamic Elastic Support: TPU foam enhances side bolster comfort for long-distance driving.

Lightweight Design: TPU composites reduce weight by 15–20% compared to traditional foam + steel structures.

(3) Functional Seat Components

Adjustable Lumbar Support: TPU air cushion layers in electric seats offer better durability than conventional air bladders.

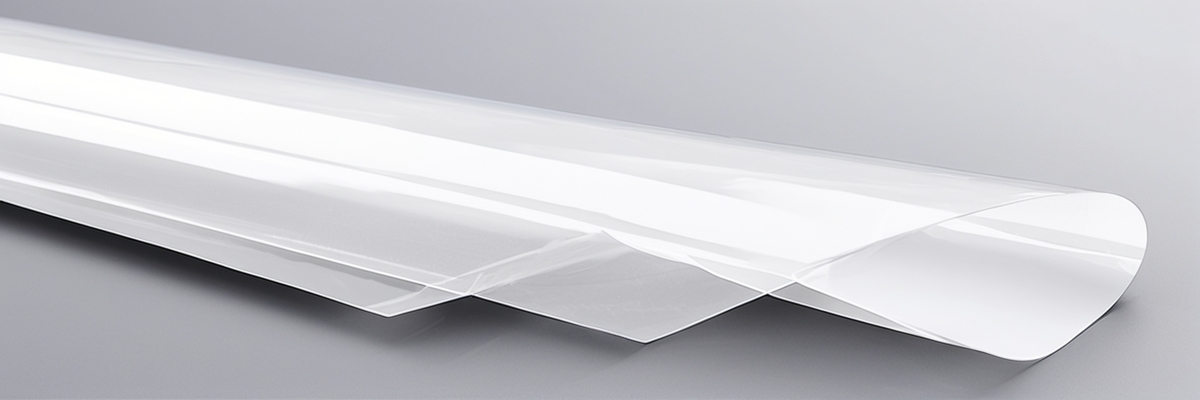

Ventilation/Heating Layers: TPU films integrate heating wires or airflow channels for enhanced comfort.

(4) Child Safety Seats

High Impact Absorption: TPU cushioning meets ECE R129 safety standards.

Non-Toxic & Eco-Friendly: Free from PVC plasticizers, ensuring child safety.

2. Advantages of TPU in Automotive Seats

| Property | TPU | Genuine Leather | PVC/PU Leather |

|---|---|---|---|

| Abrasion Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ |

| Weather Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

| Eco-Friendliness | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Lightweight | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

| Cost | ⭐⭐⭐ | ⭐ | ⭐⭐⭐⭐ |

✅ Key Benefits:

Longer lifespan (10+ years without cracking)

Extreme temperature resistance (-40°C to 120°C)

Compliance with regulations (EU ELV, China GB)

3. Future Trends

(1) Smart Seat Integration

Haptic Feedback TPU: Used in autonomous driving seats for vibration alerts (e.g., BMW iX concept).

Self-Healing TPU Coatings: Minor scratches repair automatically, enhancing luxury appeal.

(2) Bio-Based TPU Adoption

Renewable materials (e.g., corn, castor oil) reduce carbon footprint (e.g., BASF’s bio-based TPU).

(3) 4D Breathable TPU Structures

Laser-perforated TPU + 3D mesh improves airflow (similar to Adidas 4D midsole tech).

4. Challenges & Solutions

| Challenge | Solution |

|---|---|

| Higher Cost | Scaling production + recycled TPU |

| Low Consumer Awareness | Marketing as "Tech Leather" (e.g., NIO) |

| Softening at High Temp | Heat-resistant TPU (e.g., ceramic additives) |

Conclusion

With durability, lightweighting, and sustainability advantages, TPU is transforming automotive seating. As smart and bio-based innovations advance, TPU is poised to become the standard material in mid-to-high-end vehicles, gradually replacing leather and PVC/PU.