Application Prospects of TPU Leather in the Automotive Industry

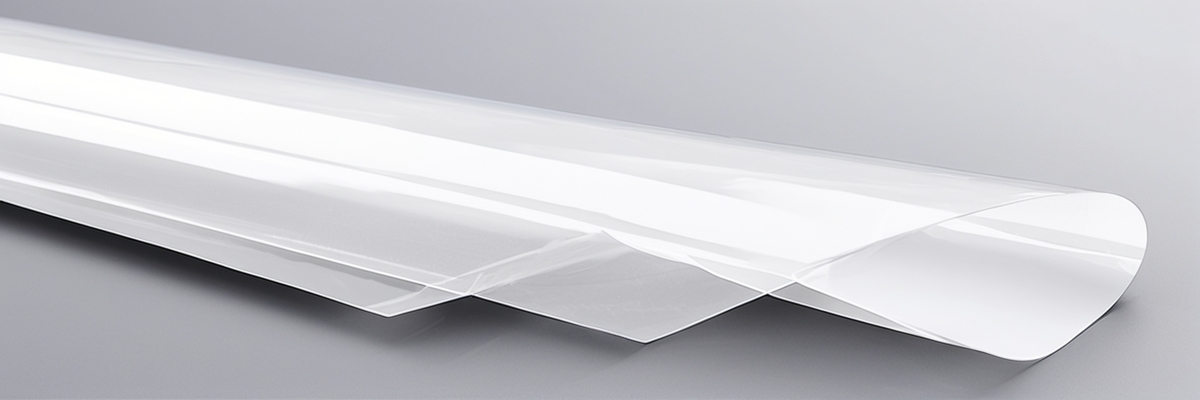

TPU (Thermoplastic Polyurethane) leather is emerging as a high-performance synthetic material in the automotive sector, gradually replacing traditional genuine leather and conventional synthetic leathers (e.g., PVC/PU). Its superior physical properties and environmental advantages make it a compelling alternative. Below is an analysis of TPU leather’s current applications and future prospects in the automotive industry.

1. Core Advantages of TPU Leather

Exceptional Performance

Weather Resistance: UV-resistant, stable across extreme temperatures (-40°C to 120°C), outperforming PVC/PU (which may crack or become sticky).

Mechanical Strength: High tear resistance and abrasion resistance (Martindale tests exceed 100,000 cycles).

Eco-Friendliness: Recyclable and free from phthalate plasticizers, complying with EU REACH regulations.

Manufacturing Flexibility: Can be processed via calendering, coating, or 3D printing to mimic textures (e.g., pebble grain, carbon fiber).

Cost Efficiency

Priced between genuine leather and PU leather, with potential cost reductions of 30%+ at scale.

2. Current Applications

Premium Interior Trim

Seat Surfaces: Tesla Cybertruck offers TPU leather seats for enhanced scratch resistance and easy cleaning.

Steering Wheels & Gear Knobs: Porsche Taycan uses TPU-wrapped steering wheels for durability.

Dashboards & Door Panels: Li Auto L9 employs TPU-fabric composites for a soft-touch, anti-glare finish.

Functional Components

Waterproof Storage Liners: TPU-coated fabrics prevent liquid seepage in door pockets.

Foldable Soft Parts: Used in EV trunk organizers for elasticity and lightweight properties.

Exterior Innovations

Convertible Roofs: Land Rover Defender’s optional TPU soft top outperforms traditional canvas.

Vehicle Wraps: Self-healing colored TPU films (e.g., XPEL) are popular in car customization.

3. Future Growth Drivers

Electric Vehicle (EV) Demand

Lightweight (TPU density: 1.1–1.2 g/cm³, 20% lighter than leather) and avoids the carbon footprint of leather tanning.

Brands like Tesla and BYD promote "vegan interiors," positioning TPU as a sustainable choice.

Smart Integration

Haptic Feedback: Pressure-sensitive TPU surfaces (e.g., BMW iX’s seat controls).

Lighting Effects: Laser-perforated TPU with LED backlighting for dynamic ambient lighting.

Regulatory Push

EU’s ELV Directive mandates 95% recyclability, favoring TPU’s chemical recycling (e.g., depolymerization).

China’s Restricted Substances Regulation limits heavy metals, which TPU complies with.

4. Technological Breakthroughs

High-Performance Modifications

Self-Healing TPU: Microcapsule technology for scratch repair (currently in R&D).

Flame-Retardant TPU: Halogen-free additives for EV battery compartments (UL94 V-0 rating).

Bio-Based TPU

Companies like DuPont develop plant-based TPU (e.g., corn starch derivatives), reducing carbon footprint by 50%.

Composite Techniques

TPU + Microfiber: Combines breathability (like Alcantara®) with TPU’s durability.

5. Challenges

Cost: High-end TPU remains 20–30% pricier than PU; economies of scale are needed.

Consumer Perception: Some equate "genuine leather" with luxury; education on TPU’s benefits is crucial.

Supply Chain: Automotive-grade TPU materials (e.g., hydrolysis stabilizers) require further development.

6. Market Forecast

Penetration: TPU leather currently holds ~8% of automotive interiors; projected to reach 25% by 2030 (IHS Markit).

Regional Growth: China (EV boom) and Europe (strict eco-regulations) will lead adoption.

Conclusion

TPU leather is transitioning from a niche alternative to a mainstream automotive material, particularly in the $30K–50K EV segment. Its success hinges on:

Performance enhancements (e.g., better breathability).

Smart functionality integration.

Circular economy adoption (scalable recycling).

In the future, TPU leather may redefine "new luxury"—prioritizing sustainability and innovation over traditional leather prestige.